All You Need To Know About Reinforced Cement Concrete (RCC)

Ever wondered about the strength that holds buildings together? Dive into the world of Reinforced Cement Concrete (RCC), the backbone of modern construction. As we unravel its intricacies, you’ll discover the key properties, diverse types, and wide-ranging applications that make RCC the go-to choice for sturdy structures. Join us on this journey to understand how RCC can transform your dream home into a reality.

What Is Reinforced Cement Concrete (RCC)?

Reinforced Cement Concrete (RCC) remains a pivotal construction material renowned for its enduring strength and durability. Comprising cement, aggregates, water, and embedded steel reinforcement. Reinforced Cement Concrete (RCC) synergizes the best properties of each component. Reinforcing steel bars provides tensile strength to counterbalance concrete’s inherent weaknesses, resulting in resilient structures capable of withstanding diverse forces and loads.

RCC’s versatility spans various construction projects, from towering skyscrapers to bridges and residential buildings. Its exceptional compressive strength, durability, and resistance to stress make it a top choice. Architects and engineers leverage RCC’s adaptability to craft intricate designs while ensuring structural integrity and longevity. This amalgamation of cement and steel stands as a cornerstone in construction, contributing to enduring structures that signify engineering excellence.

Properties Of Reinforced Cement Concrete (RCC)

Here are six key properties of Reinforced Cement Concrete (RCC):

- High Compressive Strength: RCC exhibits remarkable compressive strength, making it ideal for bearing heavy loads without succumbing to deformation or structural failure.

- Excellent Durability: Its durability against weathering, chemical attacks, and environmental factors ensures longevity, making it suitable for various construction projects.

- Fire Resistance: Reinforced Cement Concrete (RCC) offers impressive fire-resistant properties, making it a safe choice for building structures that require robust fireproofing.

- Versatility: RCC’s adaptability enables architects and builders to create diverse designs, from intricate structures to robust foundations, owing to its moldability in various shapes and forms.

- Tensile Strength with Steel Reinforcement: The integration of steel reinforcement within concrete significantly enhances its tensile strength, mitigating cracking and reinforcing structural stability.

- Reduced Maintenance: Its low maintenance requirement due to its durability and resistance to environmental degradation ensures cost-effectiveness over the lifespan of the structure.

Composition Of Reinforced Cement Concrete (RCC)

The composition of Reinforced Cement Concrete (RCC) involves a meticulous combination of several essential components to achieve the desired strength and durability. Here’s a breakdown of these key elements

1. Cement:

Cement serves as the binding agent in Reinforced Cement Concrete (RCC), creating a cohesive matrix that holds the other components together. Portland cement, a commonly used type, undergoes chemical reactions with water to form a solid, durable structure.

2. Aggregates

- Coarse Aggregates: These larger particles, such as gravel or crushed stones, provide strength and stability to the concrete mix. Their size and shape influence the workability and structural integrity of the final product.

- Fine Aggregates: Comprising smaller particles like sand, fine aggregates fill the voids between coarse aggregates, enhancing the overall compactness and workability of the concrete mix.

3.Water:

Water acts as the catalyst for the hydration process in cement, facilitating the chemical reactions that lead to the hardening and setting of the concrete. The right water-to-cement ratio is crucial for achieving the desired strength.

4. Reinforcement Bars/Mesh:

Steel reinforcement, in the form of bars or mesh, is incorporated to provide tensile strength to the concrete. The steel and concrete work together as a composite material, ensuring the structure can withstand both compressive and tensile loads effectively. This reinforcement prevents cracking and enhances the overall durability of the Reinforced Cement Concrete (RCC).

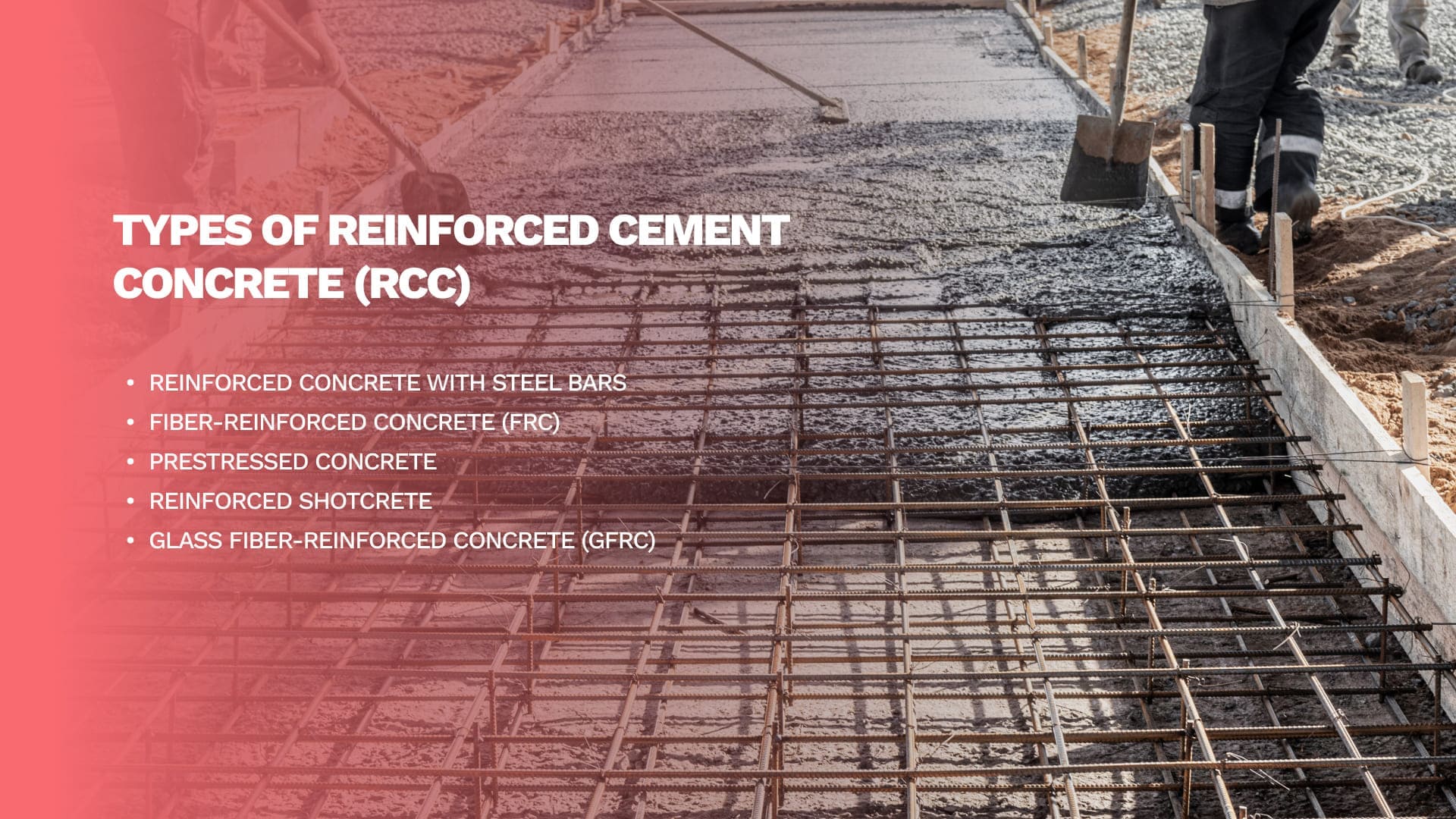

Types of Reinforced Cement Concrete (RCC)

Reinforced Cement Concrete (RCC) exhibits versatility through various types, each engineered to serve specific purposes and enhance structural capabilities:

1. Reinforced Concrete with Steel Bars:

The most common type, where steel bars or rebars are strategically placed within the concrete to reinforce it against tension. This type excels in withstanding bending and stretching forces.

2. Fiber-Reinforced Concrete (FRC):

Integrates fibers—such as steel, glass, or synthetic fibers—into the concrete mixture to enhance toughness and flexibility. FRC minimizes cracking and improves resistance to impact and fatigue.

3.Prestressed Concrete:

Utilizes pre-tensioning or post-tensioning techniques to introduce compressive stresses into the concrete. This method increases its load-bearing capacity and allows for more extended spans without excessive deflection.

4. Glass Fiber-Reinforced Concrete (GFRC):

Combines glass fibers with the concrete mix, creating a lightweight and durable material. GFRC offers versatility in design, enabling intricate shapes and textures for architectural applications

5. Reinforced Shotcrete:

Involves projecting or spraying a concrete mix, often with added reinforcement, onto surfaces. This method offers rapid construction and is suitable for curved or complex structures, providing a durable finish.

Applications Of Reinforced Cement Concrete (RCC)

Reinforced Cement Concrete (RCC) finds extensive applications across various construction domains owing to its durability and strength. Here are some prevalent applications:

- Buildings and Residential Structures: Reinforced Cement Concrete (RCC) is widely used in constructing residential buildings, apartments, villas, and individual homes due to its robustness and ability to withstand various loads.

- Bridges and Flyovers: RCC’s superior tensile strength makes it a preferred choice for building bridges, flyovers, and overpasses, providing the required stability and durability for heavy traffic.

- Dams and Canals: RCC’s durability and water resistance make it suitable for constructing dams, reservoirs, and canals, where it withstands water pressure and maintains structural integrity.

- Industrial Structures: RCC serves in industrial settings for constructing warehouses, factories, and other structures, providing sturdy frameworks for heavy machinery and equipment.

- Roads and Pavements: RCC is employed in constructing road dividers, sidewalks, and pavements, offering durability and resilience against traffic loads and environmental conditions.

- Retaining Walls and Foundations: It’s commonly used in retaining walls and foundations due to its ability to withstand lateral pressure and provide stability to the structure.

- Water Tanks and Reservoirs: RCC’s impermeability makes it ideal for constructing water tanks, reservoirs, and sewage treatment plants, preventing water seepage and ensuring durability.

- High-Rise Constructions: For tall buildings and skyscrapers, RCC serves as the primary material for the structural framework, ensuring stability and safety against seismic forces and other loads.

Factors To Consider Before Going for Reinforced Cement Concrete (RCC)

Before opting for Reinforced Cement Concrete (RCC) in your construction project, several factors warrant consideration:

- Structural Requirements: Evaluate the project’s load-bearing needs, seismic conditions, and environmental factors to determine if Reinforced Cement Concrete (RCC) suits the structural demands.

- Budget and Cost Analysis: Assess the overall budget, including material costs, labour expenses, and long-term maintenance, to ensure feasibility.

- Testing and Quality Assurance: Implement stringent quality checks and regular testing procedures at various stages of construction to ensure compliance with industry standards and maintain structural integrity.

- Site Conditions: Analyze the site’s soil quality, geographical aspects, and environmental elements to verify RCC’s suitability.

- Mix Design: Collaborate with experienced engineers to determine the precise mix proportions of cement, aggregates, and water, optimizing the concrete’s strength and durability.

Conclusion

In the intricate dance of construction, Reinforced Cement Concrete (RCC) emerges as the lead. Its unparalleled strength and versatility make it an indispensable choice. As you envision your dream home, TeamHome stands ready to translate those dreams into a concrete reality. We, the best construction company in Bangalore, bring expertise, transparency, and efficiency to ensure your home-building journey is seamless and stress-free. Let’s build together!